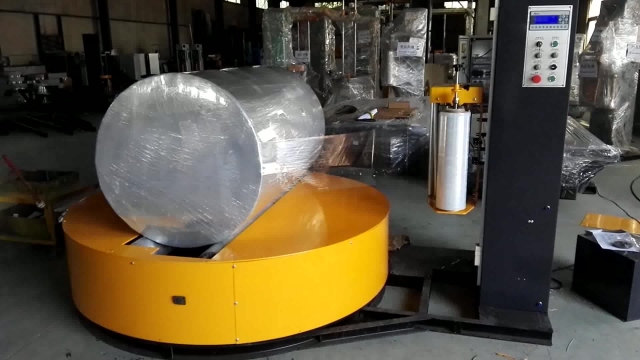

In today’s fast-paced world of logistics and warehousing, efficiency and productivity have become paramount. One innovation that has revolutionized the industry is the stretch wrapper, a powerful tool designed to streamline the pallet wrapping process. By securely anchoring and sealing products to pallets, this machine ensures stability and protection during transportation, storage, and handling. With its ability to stretch and wrap plastic film tightly around pallets, the stretch wrapper has become an integral part of modern supply chains.

Also known as a pallet wrapping machine or pallet wrapper, the stretch wrapper offers a range of benefits that extend beyond its primary function. By automating the wrapping process, businesses can significantly reduce labor costs and enhance overall productivity. This allows employees to spend their time and energy on other crucial tasks, maximizing efficiency across the board. Moreover, the stretch wrapper eliminates the need for manual wrapping, ensuring consistent and reliable performance every time.

The versatility of the stretch wrapper further contributes to its appeal. With various models and configurations available, businesses can choose the one that best suits their needs. From semi-automatic to fully automatic options, the stretch wrap machine can accommodate different load sizes and film thicknesses. This adaptability ensures that regardless of the industry or product, the stretch wrapper can be tailored to provide optimal results.

In our increasingly eco-conscious society, sustainability has become a key consideration for businesses. The stretch wrapper plays a part in this, as it allows for the use of thinner plastic films without compromising load stability. This not only reduces material waste but also cuts down on overall packaging costs. By adopting a stretch wrapper, companies can actively contribute to eco-friendly practices and bolster their reputation as environmentally responsible entities.

In conclusion, the stretch wrapper is a game-changer in the world of pallet wrapping machines. Its efficiency, versatility, and sustainability make it an indispensable tool for businesses across industries. By investing in this technology, companies can unlock the full potential of their supply chains, ensuring secure and cost-effective transportation of goods. With the power of the stretch wrapper, the possibilities are truly endless.

Benefits of Using a Stretch Wrapper

Using a stretch wrapper, also known as a pallet wrapping machine or pallet wrapper, offers several advantages for businesses. This powerful tool in the packaging industry can revolutionize the way goods are prepared for shipment or storage. Let’s explore the key benefits of utilizing a stretch wrapper, or stretch wrap machine, in your operations.

Efficient Wrapping Process:

A stretch wrapper streamlines the pallet wrapping process, saving valuable time and effort. With its automated features, it eliminates the need for manual labor to wrap pallets, reducing the risk of errors and ensuring consistent wrapping quality. This efficiency enables workers to focus on other essential tasks, ultimately increasing overall productivity within your organization.

Enhanced Load Stability:

Load stability is crucial when it comes to transporting goods securely. By utilizing a stretch wrapper, you can significantly improve load stability and minimize the risk of product damage during transit. The machine’s tight and uniform stretch wrap application creates a secure bond, preventing items from shifting or toppling over while in transit, reducing the likelihood of costly accidents or breakages.

Cost Savings:

Implementing a stretch wrapper can lead to significant cost savings for businesses. By utilizing machine automation, you can reduce labor costs associated with manual pallet wrapping. Moreover, the ability to apply the optimal amount of stretch film consistently means less wastage, resulting in reduced material expenses. Additionally, improved load stability translates into lower product loss due to damage, ultimately saving your company money.

In conclusion, integrating a stretch wrapper into your packaging process offers numerous benefits. With its efficiency, enhanced load stability, and cost-saving advantages, this pallet wrapping machine can optimize your operations, boost productivity, and help protect your valuable goods.

Choosing the Right Stretch Wrap Machine

When it comes to selecting the perfect stretch wrap machine, there are a few factors to consider. Firstly, the size and weight of the pallets you will be wrapping play a crucial role. Different stretch wrap machines have varying weight and load capacity limitations, so it is important to choose one that can handle the demands of your specific operation.

Secondly, the throughput of your packaging line should be taken into account. If you have a high-volume production environment, it would be wise to opt for a stretch wrap machine that offers fast and efficient wrapping capabilities. On the other hand, if your operations involve lower volumes, a machine with a slower wrapping speed may be a more cost-effective choice.

Lastly, the type of film you will be using is an important consideration. Some stretch wrap machines are designed to work with a particular film thickness or width, while others offer more flexibility in terms of film options. It is crucial to ensure that the machine you choose can accommodate the specific film requirements of your application to achieve optimum load stability and protection.

By carefully evaluating these factors, you can identify the stretch wrap machine that best matches your pallet wrapping needs. Investing in the right machine will not only improve efficiency and productivity but also contribute to the overall quality and safety of your palletized products.

Tips for Effective Pallet Wrapping

- Proper Load Placement

Ensuring proper load placement is crucial for effective pallet wrapping. Before applying the stretch wrap, make sure the load is evenly distributed on the pallet. This helps to maintain stability during transportation and storage. It is also recommended to place heavier items at the bottom and lighter items on top to maintain balance. Taking the time to arrange the load correctly will greatly enhance the effectiveness of the stretch wrapping process.

Stretch Wrapping

- Select the Right Stretch Wrap Machine

Choosing the right stretch wrap machine is essential for achieving optimal results. Consider factors such as the volume of pallets to be wrapped, load weight, and the desired level of automation. There are various types of pallet wrapping machines available, including semi-automatic and fully automatic models. Determine the specific needs of your operation and select a machine that best suits your requirements. Investing in a high-quality stretch wrap machine will improve efficiency and ensure consistent wrapping performance.

- Apply Sufficient Stretch

Applying sufficient stretch to the stretch wrap is vital for securing the load effectively. The stretch wrap should be taut enough to hold the items in place while allowing for some elasticity. This helps to prevent shifting or damage during transportation. Be mindful not to overstretch the wrap, as it may lead to tearing or the load becoming unstable. Finding the right balance in the stretch will result in a well-wrapped and secure pallet.

Following these tips will help unleash the power of the stretch wrapper, optimizing the pallet wrapping process and enhancing the overall efficiency of your operations. By ensuring proper load placement, selecting the right machine, and applying sufficient stretch, you can achieve effective pallet wrapping that protects your goods and improves the safety and integrity of your shipments.